By Special Correspondent André Forkert

In June elements of the Austrian Armed Forces (the Theresian Military Academy and 4 Panzergrenadier Brigade) took part in the Waldviertel 25 exercise, alongside troops from the armed forces of Germany, the Czech Republic, Latvia, Switzerland, Hungary, Bosnia and Herzegovina and Montenegro. A so-called hybrid exercise, with 1,850 Austrian troops and 250 allied soldiers while additional forces were simulated, offered an opportunity for the Austrian troops to practice their ‘Mission Forward’ concept for national defence.

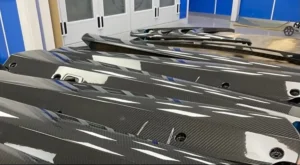

Part of the exercise involved trenching and this was the ideal opportunity for testing and evaluating the new modular plastic trenching system – the ROM Trenching System – developed by Germany’s Romold GmbH. Previously trialled by the German Military Engineering School (Pionierschule) in Ingolstadt, the system has been proven in both training and realistic combat scenarios. It uses a high tech ‘groove and click’ system, clearly visible in the accompanying images.

Protection of deployed troops is a top priority in any military operation – especially when it comes to static defensive positions. That philosophy has been amply reinforced by the conflict in Ukraine. Traditional trenching systems made of wood or corrugated iron have offered proven protection for decades, but they also have disadvantages: high logistical costs, long set-up times, noisy construction methods and low reusability. Against this backdrop, in 2025, the Pionierschule tested the first production-ready plastic combat trench – the ROM Trench System. In 2023 the school tested a prototype to collect initial empirical values. Built at the Lehnin military training area, this system was also used to train units from Ukraine.

During the Waldviertel 25 exercise, a deliberate decision was taken to use an innovative trench system – the ROM. The pre-assembled system is designed for rapid deployment: a squad of four officer cadets from the military academy built an approximately 18-metre-long trench, including a combat position within three hours. “The time savings are enormous. What used to take at least a day is now ready for use in no time,” commented an instructor from the academic battalion.

The major advantage lies in its modular design: the pre-assembled metal frame elements are set up on site and connected to the plastic wall and ceiling elements using simple plug connections. No noise from machines or tools is required, as the components can be assembled almost silently. This can be a life-saving factor, especially when operating under enemy observation. Nevertheless, an excavator is of course advantageous. “Noise and time are decisive factors, especially in this age of comprehensive reconnaissance by drones. Anyone who digs too long or too loudly today will not be able to fight tomorrow,” as one ensign put it succinctly.

Col. Fleischmann, commander of the Academic Battalion, pointed out why trench systems are once again important, even for a neutral country like Austria. “Our neutrality obliges us to be capable of self-defence. The geopolitical situation has changed fundamentally in recent years. We must assume that classic national defence will once again become more important – even in Austria. This also includes trench construction. It is a fundamental component of tactical defence and therefore important for every infantry unit. The fact that we can now use a system that is modern, efficient and tactically useful significantly strengthens our training and operational capabilities.”

The combat trench built during the exercise was not only constructed, but also used under realistic conditions: it was filled with earth, soldiers moved around in it in full combat gear, and deliberately provoked stress tests were carried out. The system held up. “We really put the whole thing to the test. No bending, no settling. The system appears to be robust and is clearly suitable for multiple use”, commented a staff sergeant from the Allentsteig military training area in Austria. The tests carried out show one thing above all: the plastic system offers clear advantages over the types of trenches used to date.

Tried and tested legacy wooden systems are heavy, bulky and consume material that is usually disposed of or burned after use. A military engineering officer who built a wooden shelter on site and observed the neighbouring plastic construction section commented: “Our previous systems – especially wood – require a lot of manual labour, time and expertise. The plastic solution, on the other hand, is almost self-explanatory. After a short training session, even infantrymen with no experience can take over the construction. This relieves our military engineers, allowing them to supervise several construction sites at the same time or be deployed to other areas of focus. In an emergency, this gives us operational advantages.”

An additional advantage is that the system components are completely reusable. After the exercise, they were cleaned, stored and will be available for future use. A sustainable approach – both ecologically and economically sensible. A remarkable side effect is that the new system facilitates cooperation between military engineers and infantry units. “In the past, we as military engineers often spent days on site because the installation of wooden systems required a great deal of expertise. Now we set up the position, the infantry takes over, and we move on – this saves time and gives the troops more independence”, explained a sergeant from the training unit.

This type of modular cooperation is exactly in line with the mission-type command approach: troops act independently within the framework of the overall plan – with the right tools, even when building positions. In addition, the tool-free click and plug system – similar to the Lego principle – offers further advantages, precisely because it can be implemented by soldiers without prior construction knowledge. With the successful installation and intensive use of the plastic trench system as part of a tactical combat exercise, the Austrian Armed Forces are demonstrating that modern defence requires modern means.

The ROM trench impressed with its ease of use, high stability, tactical advantages and sustainable reusability. What began as a prototype in Lehnin in 2023 is now on its way to being used by troops in Austria. The positive feedback from practical use and the concrete experience gained from the exercise at the Allentsteig military training area suggest that this system could remain in place – as part of modern national defence, even in a neutral state.

Image (top): The modular nature of the ROM system allows even inexperienced soldiers to assemble and commission a trench in a very short timeframe. (All images Austrian Armed Forces)